Ordinance 090:2022

Plugs and Sockets

Learn more about this certification

Objective

Product certification is a crucial requirement for marketing items in both national and international markets. By adhering to all necessary criteria, certification enhances the product’s value, affirming its verified quality and promoting it with credibility.

Ordinance 090:2022 of 09/03/2022 came into effect on 04/01/2022. Replacing Ordinance 085:2006.

Scope of certification

Certified products:

- Plug: A device consisting of a base with conductive pins that are inserted into the contacts of a socket. It also includes the necessary components to secure the electric cable that supplies power to it.

- Socket: A device with internal terminals that are energized to receive contact from the pins of a plug. It also features a mechanism to retain the connection of the conductors.

- Fixed socket: A device fixed to the wall that allows the plug of an electrical or electronic appliance to be connected and is directly connected to the mains supply.

- Mobile socket: A socket designed to connect flexible cables, energizing its contacts and allowing it to be moved while still connected to the power supply circuit.

- Multiple socket: Commonly known as power strips, these devices connect multiple appliances to a single electrical outlet and can be moved to locations away from fixed power points in the room.

- Appliance sockets: A device intended to be incorporated into or fixed to appliances that use electrical energy.

- Removable plug or removable mobile socket: Devices designed as a single unit to include a flexible cable in a single piece for use together.

- Connector cord: An assembly comprising a flexible cable equipped with a plug and a single connector, intended to connect an electrical appliance to a power supply network.

- Extension cord: An assembly consisting of a flexible cable equipped with a plug and one or multiple mobile socket outlets.

| Certification Model | Model 5 |

|---|---|

| Process Conditions: | Type tests with evaluation of the quality management system (definitive certification) |

| Certificate Validity: | 6 years |

| Valid for: | Product family certified |

| Main Stages: | - Document analysis - QMS audit at the factory - Laboratory test |

| Maintenance: | Every 6 months (with audit and test) |

| Recertification: | Every 6 years, with full type test |

Maintenance Stages: After the Certificate of Conformity is granted, Associação IEx monitors the Certification at six-month intervals (every six months) to ensure that the technical and organizational conditions registered at the start of the process continue to be met. This monitoring includes a Maintenance Audit of the Quality Management System and Maintenance Testing of the certified products.

Certification Model 1b - Batch test.

This certification process does not require a factory audit or maintenance tests.

For batch certification, the following process is required:

- Technical Documentation

- • Carry out complete type tests according to the number of products and conduct batch inspection tests in accordance with ABNT NBR 5426:1985 Corrected Version:1989, with a double-normal sampling plan, general inspection level I, and an AQL of 0.25:

Main standards used: ABNT NBR NM 60884-1:2010: Establishes the tests and checks to be performed at each stage requiring testing;

ABNT NBR 14136:2012: Establishes the criteria for conducting tests according to the specifications of the certified product.

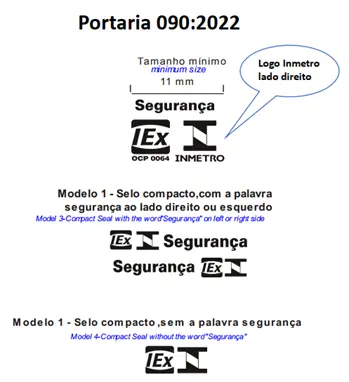

Labels

Conformity Identification Label:

After the certificate is issued, the following seal must be placed on the product and packaging:

The Conformity Identification label model below must be displayed on each product and its packaging in a legible and indelible manner:

Full model (preferred)

Compact label