Inmetro Ordinance 384:2020, dated 12/18/2020, establishes the conformity assessment requirements for equipment under the Health Surveillance regime, as outlined in ANVISA RDC No. 27 of 2011 or its substitute.

The technical standards for certifying equipment's conformity under the Health Surveillance regime defined in Anvisa Normative Instruction IN No. 116 of 2021.

Starting thirty-six (36) months from the publication date of Ordinance 384:2020, national manufacturers and importers must manufacture or import into the national market only equipment that complies with the Health Surveillance Regime as specified in the Ordinance.

| Certification Model | Model 5 |

|---|---|

| Process Conditions: | Type tests with evaluation of the quality management system (definitive certification) |

| Certificate Validity: | Indeterminate |

| Valid for: | Product family certified |

| Main Stages: | - Compliance document analysis - QMS audit at the factory - Laboratory testing |

| Maintenance: | Every 15 months, without testing (if there are no changes to the initial product) |

| Recertification: | Not applicable |

With the publication of Ordinance 254:2021, which amends Ordinance 384:2020, the following deadlines for the revocation of Ordinances 350:2010, 054:2016, and 544:2016 must be observed:

The technical standards for certifying equipment's conformity under the Health Surveillance regime defined in Anvisa Normative Instruction IN No. 116 of 2021.

Starting thirty-six (36) months from the publication date of Ordinance 384:2020, national manufacturers and importers must manufacture or import into the national market only equipment that complies with the Health Surveillance Regime as specified in the Ordinance.

| Ordinance | Revocation Date |

|---|---|

| 350:2010 | April 30, 2023 |

| 054:2016 | December 17, 2023 |

| 544:2016 | December 17, 2023 |

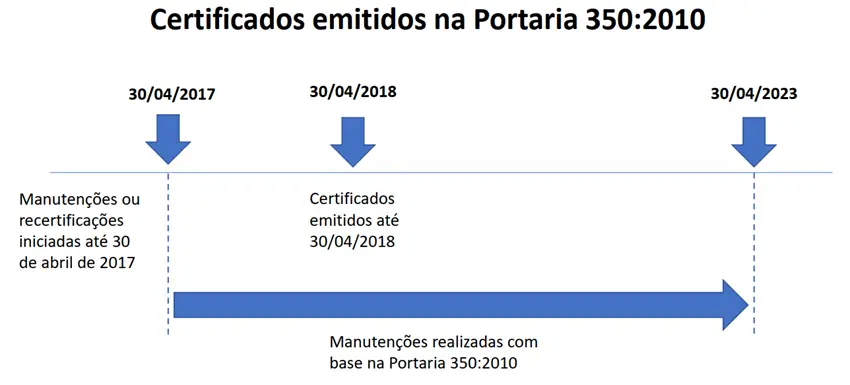

Maintenance of certifications or recertifications initiated up to April 30, 2017, may still be maintained based on Ordinance 350:2010, up to the validity limit of five (5) years for certificates issued until April 30, 2018:

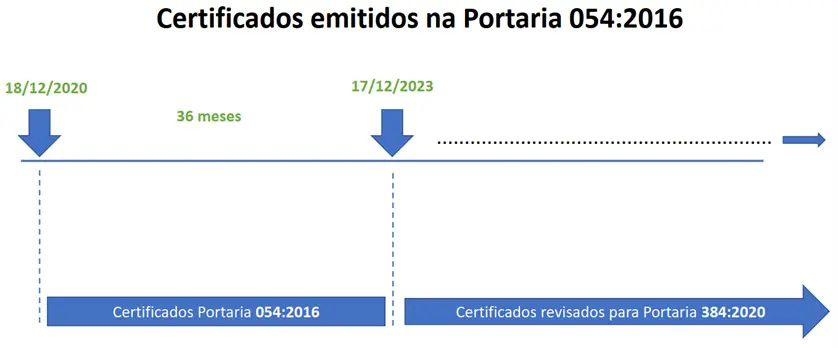

For certificates already issued based on Ordinance 054:2016, certification processes must be adapted to comply with Ordinance 384:2020 by 17/12/2023:

The new Ordinance introduces essential changes to INMETRO certification processes.

The QMS audit at the manufacturer is mandatory. As an alternative to the OCP audit, the following processes may be used:

- Evaluation of the latest ISO 13485 report;

- Analysis of the latest audit report from other OCPs accredited by Inmetro;

- Analysis of the latest “Certification of Good Manufacturing and Control Practices” report

- Evaluation of audit reports from the “Medical Device Single Audit Program - MDSAP.

Note: If the product is not in production during the audit period, the OCP must evaluate the QMS procedures and records related to the manufacturing process.

The RMS audit at the manufacturer is mandatory. However, if the OCP justifies this in the audit planning, some of the audited elements can be conducted outside the factory, at the OCP.

The OCP must provide documentary justification for each requirement assessed outside the factory.

The OCP established in Brazil must prepare the “Audit Plan” and conduct the initial audit of the QMS and RMS at the plant during the initial assessment stage.

To utilize test reports conducted before the OCP was hired and presented by the applicant in the initial documentation, requirement 6.2.4.1.3 of Ordinance 384:2020 must be fully met.

The Certificate of Conformity WILL NOT EXPIRE once maintenance activities have been carried out, including:

- Updating the RHProj;

- Maintenance audits;

- Complementary tests if there is a design change that affects the safety of the equipment.

- The OCP must schedule periodic maintenance audits of the manufacturer's production process or the service provider.

- The OCP must witness routine tests on the production line whenever applicable. Alternatively, records of tests can be used to demonstrate compliance with this requirement.

- If the OCP cannot witness the operation of the assembly line even during the maintenance audit, records of tests already conducted can be used to show compliance with this requirement.